Calisthenics

-

Handstand For Beginners

LEARN MORE -

Calisthenics for Beginners

LEARN MORE -

Build Muscle With Rings

LEARN MORE -

Bigger Legs, No Gym.

LEARN MORE -

Master the Planche

LEARN MORE -

Mix Weights & Calisthenics

LEARN MORE -

Side Split Flexibility

LEARN MORE -

Full Body Flexibility

LEARN MORE -

One Arm Pull-Up

LEARN MORE -

Master the Front & Back Lever

LEARN MORE

-

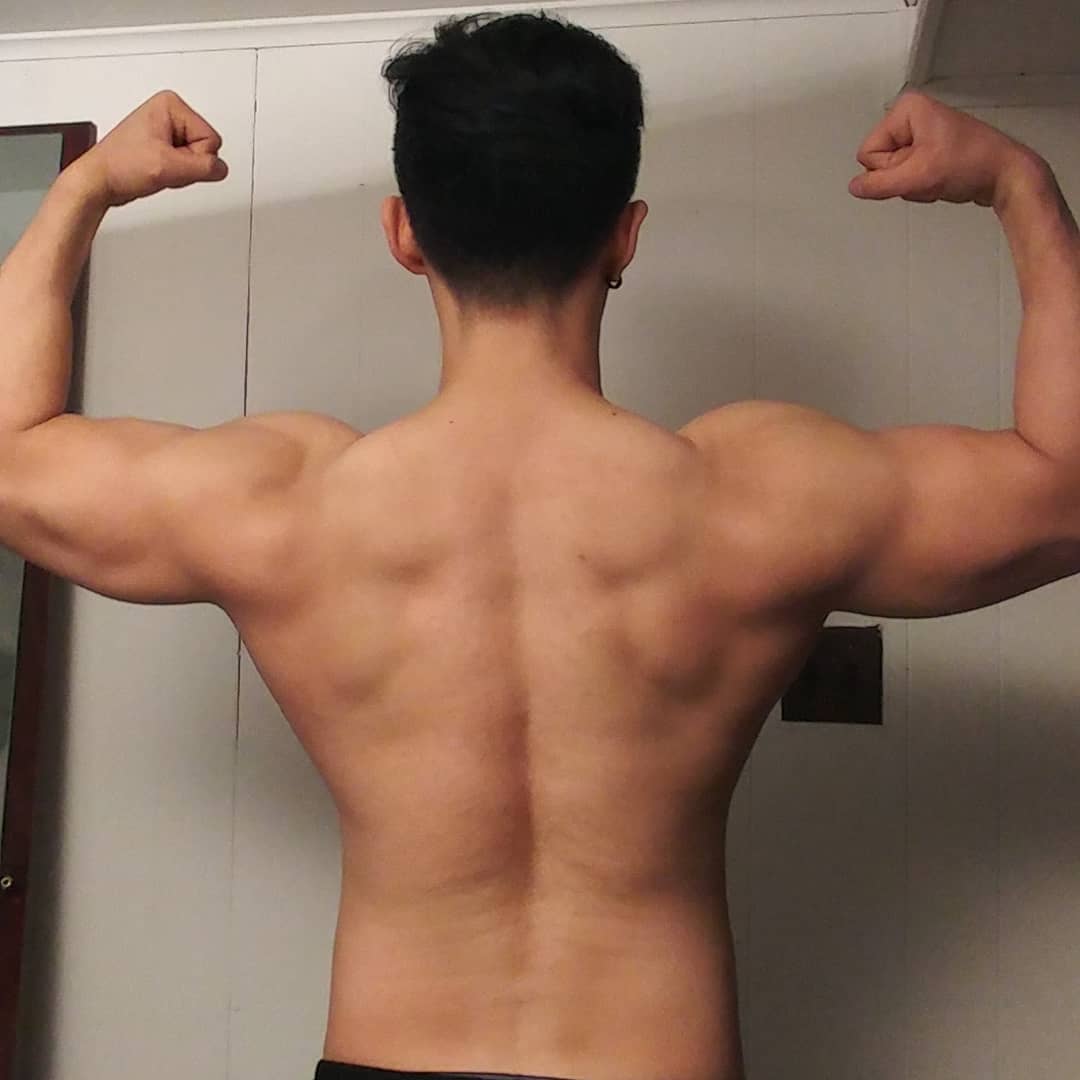

Jorge

I started at 71 kg and after 18 weeks I am at 75 kg (176cm), I really enjoyed the routine and I'm happy with results.

19, Germany. -

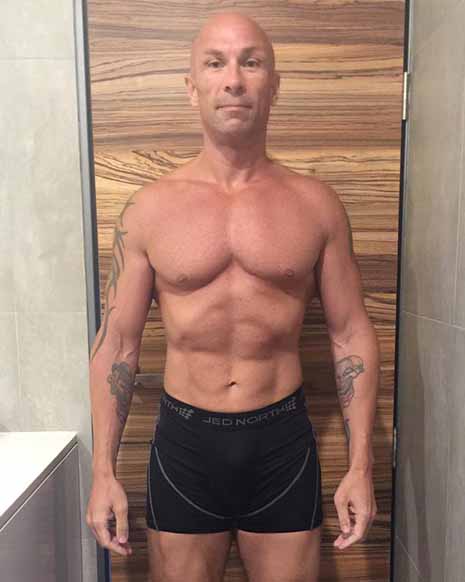

Will

I realized I was 30 and that before I get too old, I should stop half assing my routine. So I did some research and...

30, USA. -

Nils

Body By Rings has transformed my life. I've gone from a 100kg heavy guy who played games all day to a 80kg new me.

29, UK. -

BG

Lifting weights made me get lazy with my eating. Calisthenics training with body by rings helped me get leaner by focusing on bodyweight strength.

New Zealand. -

Matt

Mixing calisthenics and weights is a game changer with the Hybrid workout. I've gained 2kg in 3 months at a lower body fat level.

26, Australia -

Dan

I weighed in at 208lbs at 5’7" and decided to start eating better. I've been following Body By Rings and loving it. This past week...

35, USA -

Jan

Buying Body By Rings was a revelation, it brought my gains to a new level. FINALLY my arms which were lagging behind started to grow...

18, Germany -

Simon

I’m proud of my progress since following Begin Bodyweight. My body is a direct result of consistency, hard work, diet and minimal supplements. I weigh...

32, UK. -

Bjorn

Using bodyweight training with Limitless Legs has been a game changer. As someone over 40, calisthenics is friendly on my joints but amazing for building...

42, Australia. -

Bux

I recommend this workout for anyone looking for a fun workout to build muscle and enjoys gymnastics rings. I went from 185lbs, 18.5% body fat...

26, Spain. -

Mclain

The first photo is of me before calisthenics and the following is after my first year of strictly bodyweight training. Before I used to train...

45, Mexico. -

Jonas

Begin Bodyweight has changed the way I workout. I've realised calisthenics is the truth when it comes to muscle and strength.

22, Brasil

Need Help?

FIND THE PERFECT PROGRAM FOR YOU!

FitnessFAQs™ is a registered trademark and may not be copied or used for any purpose without express written consent. Copyright ©2020 FitnessFAQs Pty Ltd. The materials and content contained in this website, products, emails, messages, or consulting are for general health information only and are not intended to be a substitute for professional medical advice, diagnosis or treatment.

*The men and women above are exceptional examples from our community and do not guarantee individual success. Your experience and results may vary.